In the dynamic realm of construction materials, innovation knows no bounds. Glassfiber reinforced concrete (GRC), commonly known as GRFC, stands as a testament to this relentless pursuit of advancement. This remarkable material has revolutionized the construction landscape, redefining the possibilities of concrete with its enhanced strength, durability, and versatility. Today, we embark on a journey to explore the diverse world of GRC, delving into its widespread applications across various industries.

GRC in Construction: A Beacon of Strength and Efficiency

GRC has firmly established itself as a sought-after material in the construction industry, captivating builders with its remarkable properties. Its lightweight nature eases the burden on structural loads, while its resilience stands firm against the harshest weather conditions and seismic activity. From prefabricated panels to architectural facades, GRC has ushered in a new era of construction techniques, enabling faster, more efficient projects and breathtaking designs.

Key Applications:

Prefabricated Building Components: GRC’s adaptability allows for the creation of intricate prefabricated components, reducing construction time and minimizing waste.

Structural Elements: GRC’s exceptional strength-to-weight ratio makes it ideal for structural applications, such as columns, beams, and load-bearing walls, ensuring the integrity of structures.

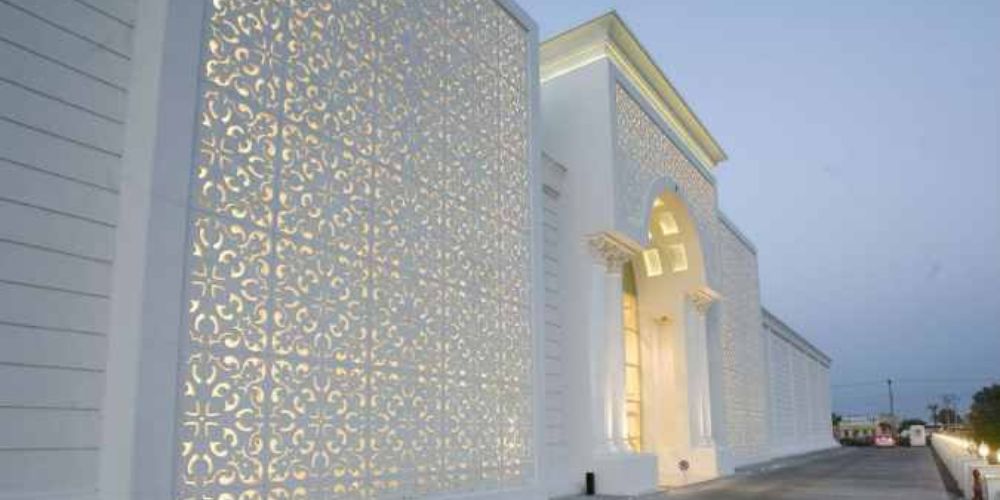

Architectural Facades: GRC’s versatility lends itself to the creation of aesthetically pleasing facades, mimicking various architectural styles with remarkable precision, adding a touch of elegance to any building.

Glassfiber Reinforced Concrete in Architecture: A Canvas for Creative Expression

Architects worldwide have embraced GRC’s potential to transform architectural designs, opening doors to limitless creative expression. Its ability to be molded into intricate shapes and textures has sparked a renaissance of architectural masterpieces, breathing new life into the built environment.

Architectural Applications:

Sculptures and Decorative Elements: GRC’s malleability makes it perfect for crafting stunning sculptures, ornaments, and decorative accents that enhance architectural designs, adding a touch of artistic flair.

Curved and Complex Structures: GRC’s flexibility defies the limitations of traditional concrete, allowing architects to create curved and intricate structures, and pushing the boundaries of architectural design.

Restoration and Retrofit: GRC’s ability to replicate historical details makes it ideal for restoring and retrofitting old buildings, preserving their architectural integrity and safeguarding their heritage.

GRC in Infrastructure: A Foundation for Longevity and Resilience

Glassfiber Reinforced Concrete’s durability and resistance to extreme conditions have made it an invaluable asset in infrastructure projects. From bridge components to tunnel linings, GRC plays a crucial role in ensuring the longevity and resilience of infrastructure assets, safeguarding the foundations of our society.

Infrastructure Applications:

Bridge Components: GRC’s lightweight strength makes it suitable for bridge decks, parapets, and other structural elements, ensuring the safety and stability of our transportation networks.

Tunnel Linings: GRC’s resistance to water and abrasion protects tunnel linings, safeguarding the integrity of underground transportation networks and ensuring the smooth flow of traffic.

Coastal Structures: GRC’s resilience against salt water and erosion makes it ideal for coastal protection structures, such as seawalls and jetties, shielding our coastlines from the relentless forces of nature.

Glassfiber Reinforced Concrete in Transportation: A Driving Force of Innovation

The transportation industry has also recognized the benefits of GRC. Its lightweight nature and durability make it a valuable material for aircraft components, railway sleepers, and vehicle parts, contributing to lighter, more efficient, and safer transportation systems.

Transportation Applications:

Railway Sleepers: GRC’s resistance to wear and tear makes it ideal for railway sleepers, ensuring the stability and longevity of railway tracks, and facilitating the smooth and safe movement of people and goods.

Pedestrian Crossings and Pathways: GRC’s durability and resistance to wear and tear make it an ideal material for pedestrian crossings and pathways. Enhancing both stability and longevity, GRC contributes to the creation of safe and well-maintained walkways, ensuring the smooth movement of people in various transportation settings.

Transit Stations Enhancements: Leveraging GRC’s versatility, it can be used for decorative elements and architectural enhancements in transit stations. Its aesthetic appeal and resistance to environmental factors make it suitable for creating visually pleasing and durable features, contributing to the overall aesthetics and functionality of transportation hubs.

Traffic Islands and Streetscape: GRC’s resilience makes it suitable for applications in traffic islands and streetscape designs. Its resistance to weathering and flexibility in design allow for the creation of robust and visually appealing features, adding both safety and aesthetic value to urban transportation landscapes.

Glassfiber Reinforced Concrete in Other Applications: A Material of Unlimited Potential

Glassfiber Reinforced Concrete‘s versatility extends beyond the realms of construction, architecture, and infrastructure. Its unique properties have led to its adoption in various industries, including furniture, landscaping, and even medical applications, showcasing its adaptability and potential for innovation.

Other Applications:

Furniture: GRC’s strength and aesthetic appeal make it suitable for high-end furniture, offering both durability and design flexibility, adding a touch of sophistication to any interior space.

Landscaping: GRC’s ability to mimic natural materials makes it perfect for landscaping elements, such as planters, fountains, and architectural features, enhancing the beauty and functionality of outdoor spaces.

Medical Applications: GRC’s biocompatibility and radiation shielding properties make it suitable for medical equipment, such as radiation shielding panels and dental molds, contributing to safer and more effective medical treatments.

GRC is the Preferred Choice for:

Architects and designers: GRC’s versatility and aesthetic appeal make it a preferred choice for architects and designers seeking to create innovative and visually stunning structures.

Builders and contractors: GRC’s ease of use, durability, and strength make it a preferred choice for builders and contractors seeking to construct efficient, long-lasting, and resilient structures.

Asset owners and managers: GRC’s low maintenance requirements, resistance to damage, and extended lifespan make it a preferred choice for asset owners and managers seeking to reduce lifecycle costs and enhance the value of their assets.

GRC: Shaping the Future of Construction and Beyond

As GRC technology continues to evolve, its impact is bound to expand, shaping the future of construction and beyond. With its remarkable properties and limitless potential, GRC is poised to play an increasingly significant role in creating sustainable, resilient, and aesthetically pleasing structures that will define the built environment of tomorrow.

Conclusion: GRC has emerged as a transformative force in the construction industry, redefining the possibilities of concrete and opening doors to a world of creative expression and innovative applications. Its versatility, durability, and strength have propelled it into various industries, from construction and architecture to infrastructure and transportation, and its impact is bound to expand as GRC technology continues to evolve. As we embrace the future of construction, GRC stands ready to shape the built environment, leaving a lasting legacy of strength, beauty, and innovation.

SUNCRETE: Leading the Way in Glassfiber Reinforced Concrete Solutions

SUNCRETE takes pride in its position as a premier GFRC supplier and manufacturer in Australia, offering a comprehensive range of high-quality products, including GRC panels, GRC bollards, and more. As a leading GRC supplier in Australia, SUNCRETE is dedicated to providing top-notch Glassfiber Reinforced Concrete solutions characterized by strength, durability, and aesthetic appeal. Committed to excellence, SUNCRETE addresses diverse construction needs across Australia, delivering innovative solutions through its extensive line of GRC panels and related products. As a trusted and evolving name in the industry, SUNCRETE blends expertise with a profound understanding of GRC technology, ensuring clients receive products that consistently meet the highest standards. When seeking reliable GRC panels in Australia, SUNCRETE stands as a go-to supplier and manufacturer, unwaveringly committed to excellence across its product range and services.